In recent years, machine vision has experienced a significant increase in the quality and performance of the available technology. Offering functionalities, even more advanced, for quality control systems, defects inspection, assembly verification, traceability, metrology, code reading and DataMatrix, robot guidance and bin picking.

We will propose the solution that best suits your needs and financial availability. Within the huge range of possibilities currently offered by technology.

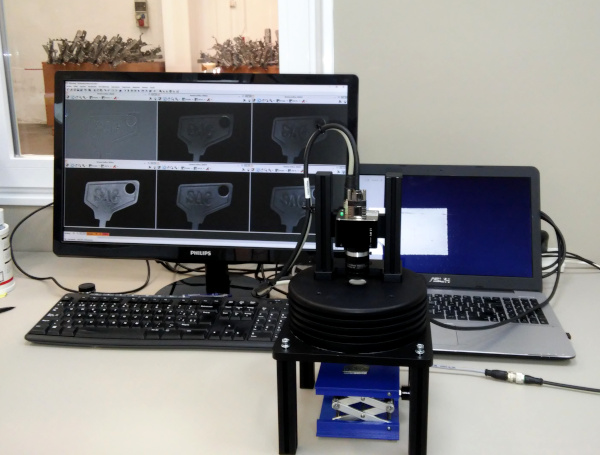

Accuracy measurement: telecentric vision.

High precision dimensional control for small parts of various materials.

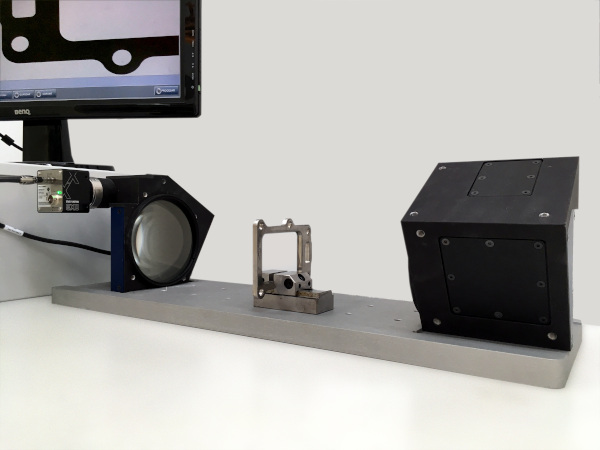

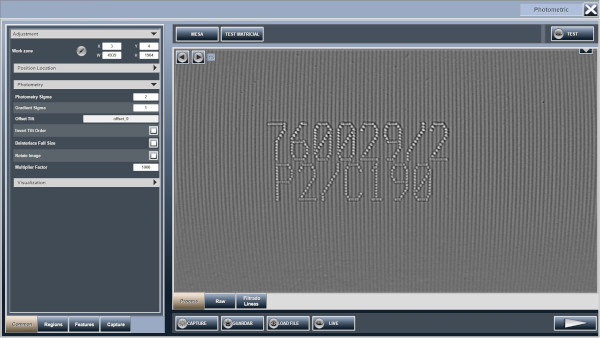

Surface imprefections: photometric stereo

High-precision quality control of surfaces where different errors arising from manufacturing processes need to be detected.

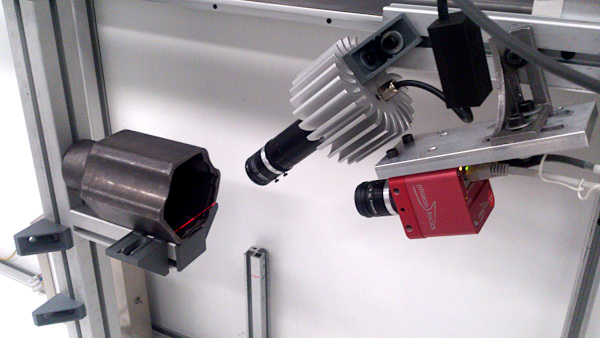

Three-dimensional vision: laser triangulation

3D object scanning that provides presence, positioning or inspection data from different parts.

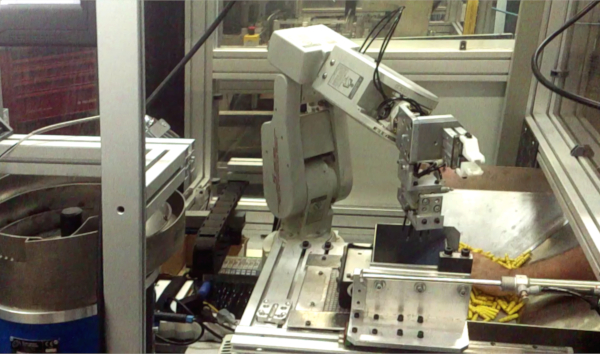

Robot Guidance and Bin Picking

Location and extraction of a container or pallet, of parts for inspection by vision and subsequent classification and / or placement.

Traceability, OCRs, DataMatrix, DPMs

Reading and storing data through different coding systems to have greater control over industrial processes.