Machine vision system for measurement and quality control at Global Steel Wire

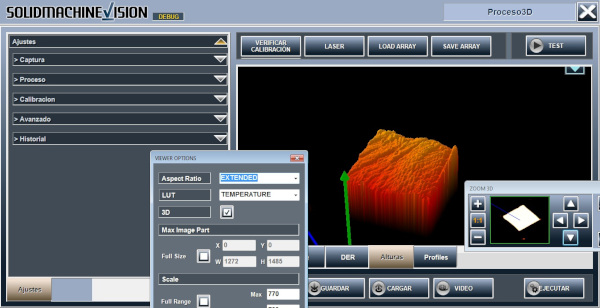

Solid Machine Vision has recently developed a quality control system with machine vision for Global Steel Wire, a steel processing plant in Santander. It is a 3D system for the measurement and quality control of billets.

The 3D system, developed with artificial vision performs both, the dimensional inspection of steel billets to control the rhomboidity and bulging, and the inspection of surface defects as, for the example, the presence of burrs and the flatness of cut, that these billets may have.

Solid Machine Vision has developed and customized an industrial software for machine vision that provides image processing, analysis and exploitation as well as the traceability of the data. It also allows you to export them to databases for the further analysis of Big Data.

Moreover, the system includes components designed specifically for this project, such as a laser specialized in high temperature metal inspection, in order to offer the complete solution to our costumer.

We know how important is quality control in steel mills and our customers are looking forward to improving the efficiency to optimize their production processes.

For all this, at Solid Machine Vision, we strive every day to meet the needs of our customers and improve and implement the best techniques of artificial vision for the challenges of the fourth industrial revolution or industry 4.0.