Automatic measurement, recording and traceability of data using machine vision technologies

Solid Machine Vision has implemented an automation solution for the automatic measurement of spindles, using machine vision technologies in SHUTON. This company develops and manufactures high precision ballscrews and is a member of the Nadella Group.

Challenges and solution

The challenge we faced was to meet the requirements of automation and digitalisation of part of the process: automatic measurement of the spindles, automatic recording and traceability of the data, as well as the generation of reports to improve the manufacturing process.

To reach these requirements, the solution implemented by Solid Machine Vision is a System for the automatic measurement of spindles with artificial vision.

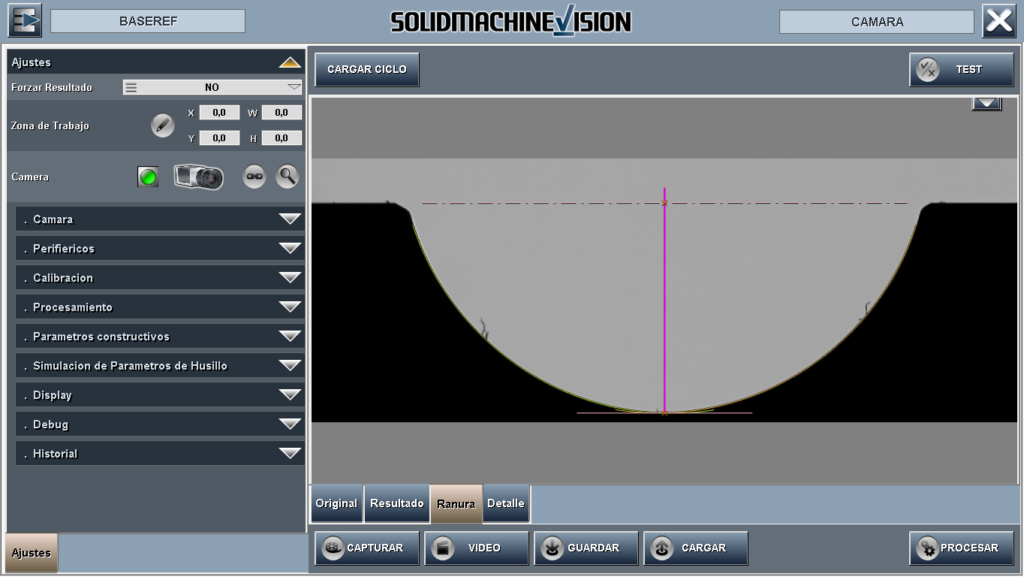

After making a study and in constant communication with the client in order to define and adapt the project properly, we designed on the one hand a layout with telecentric measurement technologies that provide high precision and on the other hand, we developed the customised software with the client’s parameters. This industrial software, developed by us in an integral way, has an intuitive and friendly interface for the work process staff that will use it.

System operation and results

As the pieces pass by, we automatically measure them with two telecentric lenses, whose dimensional images are recorded and processed by a powerful software customized for the client, based on the actions he wants to perform. Finally this data is sent and managed with an ERP.

Customised software development

The results are immediate from the implementation of the system, achieving time reduction. In short, we can speak of greater efficiency and competitiveness for the company.

At Solid Machine Vision we are specialists in turnkey solutions of machine vision and image analysis for the industry.

Contact us if you want information about machine vision solutions for your company or project. We offer you advice without obligation.