Integrated online machine vision systems to improve the competitiveness of manufacturing processes

In an increasingly competitive environment, the control of manufacturing processes requires the implementation of preventive quality measures based on technologies such as machine vision, to control and improve these processes. In this way, we will know in what status they are and we will be able to put ourselves before future unforeseen events.

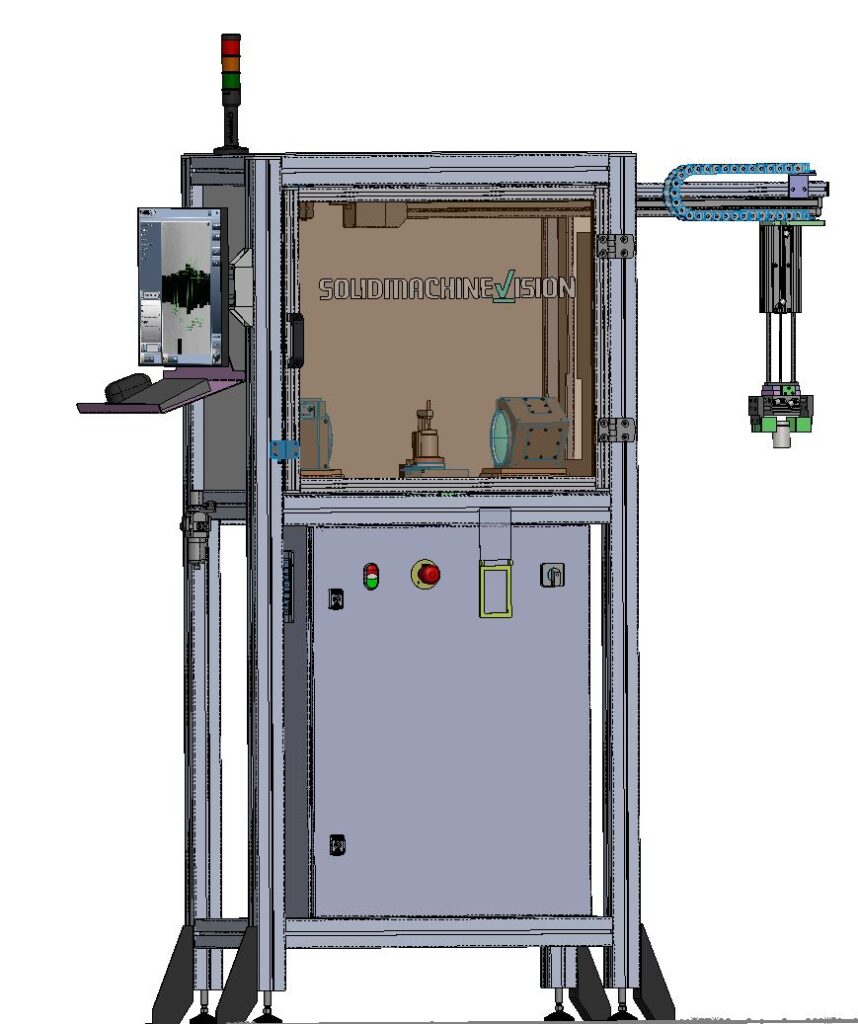

To this end, Solid Machine Vision has developed a turnkey machine vision solution in an automotive component manufacturing line. The solution aims at the frequency measurement of pistons for vision brakes.

Design and commissioning of a piston frequency measurement tool for automotive

The system consists of a turning table and probe, telecentric lens, camera and telecentric light from Opto-e. A manipulator takes a piston from the manufacturing line and places it on the turning table. The piece is rotated and the camera takes 360º images. These images are processed and the external measurements required by the customer are taken. On the other hand, the probe measures the depth of highlight on the upper face of the piston. Finally, the generated data is automatically exported to the higher-level systems for management.

In-line integrable frequency inspection system

This tool allows an automatic inspection of control of the production process, in the initial stages and without making a 100% control of parts. That is, from time to time, a piston is inspected, if it fails, it can be stopped, check the production up to that piece and try to correct the manufacturing errors that may have occurred.

By not facing the control of 100% pistons, it has been possible to simplify the equipment developed, which facilitates its integration in a simple way in the production line.

In addition, if the system fails, no more value is added to the part and the future rejection of large batches of parts is reduced, resulting in lower manufacturing costs.

Machine vision solutions for the automotive auxiliary sector

Machine vision has experienced in recent years, a spectacular increase in available technology, impacting the industry in general and the automotive sector in particular, in such a way that the control of manufacturing has become a necessity for companies to be more flexible and competitive.

If you want to know more about machine vision solutions for your company or project, contact us. We offer you advice without obligation.